Main Products / Services/ Breaking News

English

English

Mon-Fri: 9:30 a.m. to 6:30 p.m.

It is common knowledge that using connectors to connect LED light strips can improve connection efficiency and save installation time and labor cost. However, there will also be some problems in the actual application, which usually appear as follows:

The article will tell you why they happen and how to fix or avoid them.

Pull the light strip after connection

For some surface contact connectors, this will cause the conductor to not fall in the correct position of the pad, which will affect the current connection. For some pierced-to-contact light strip connectors, pulling the light strip will cause the pierced hole to become larger and the connector cannot connect to the circuit.

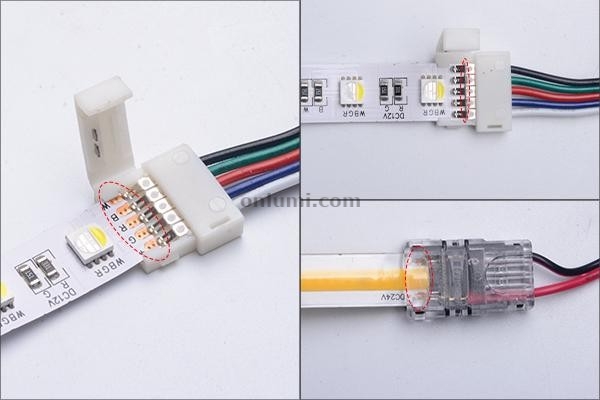

The light strip is not in the correct position

For example, when inserting the light strip, its insertion depth is not adjusted so that the hardware is placed above the pad. Or when using the pierced light strip connector, the light strip is not placed above the needle, but close to the front of the needle.

The front and back sides are mistaken

Some pierced connectors require the connector to be pierced from the back of the circuit board and fixed from the front. If the front and back sides are mistaken, the best contact and fixing force will not be obtained.

The terminal and wire rod are not done well

This is a problem of production quality control. When crimping the terminal to the wire rod with the machine, it is not checked whether it is reliable.

Overheating usually comes from the following reasons

Excessive current causes heating

Usually, the connector has a maximum current limit. If the current of the light strip exceeds the limit of the connector when connecting the light strip, it will cause the connector to overheat.

The solution is to determine the maximum current of the connector before use, calculate how much current will be generated by the light strip to be connected, and then determine how many connectors are needed to connect the light strip.

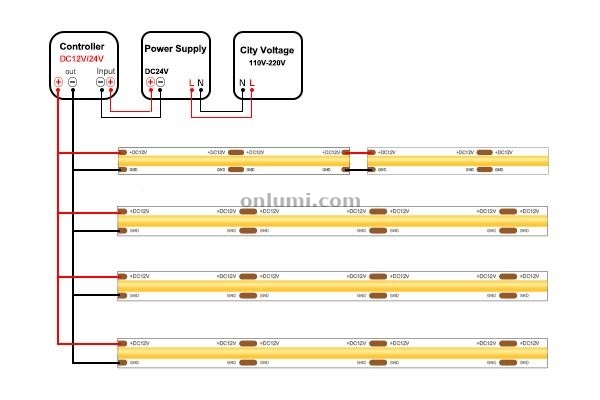

If the length required by the project causes excessive total current, it is recommended that you connect and install the light strip in the way shown in the figure below.

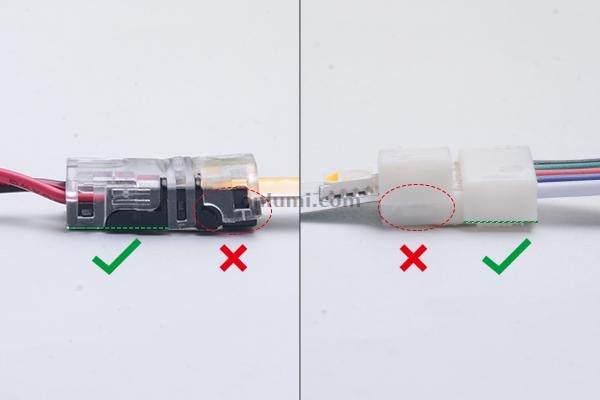

Not locked tightly

This problem can also cause serious heating of the connector. Failure to lock the connector tightly will cause insufficient contact between the conductor and the light strip pad, resulting in spark strike arc, which will generate heat and cause the connector to overheat.

The solution is to check whether the connector is locked tightly every time using it to ensure that all buckles are locked in the correct position. Do not loosen. Do not use it if it cannot be locked tightly.

Temperature resistance of shell

The temperature resistance of shell material is one of the standards to measure the quality of connector. If the temperature resistance is too low, it will cause the light strip to melt and even deform more easily. Therefore, it is necessary to test the working temperature of the conductor and check the deformation temperature of the shell material at the same time. If the temperature resistance is too low, it is recommended that you replace it with a connector from another supplier.

Real copper is not used as a conductor.

This problem causes a high proportion of connector overheating faults. In order to save costs, many low-end connectors use other metal materials as conductors instead of copper, which will increase the resistivity and reduce the overcurrent capacity. When connecting high power light strips, this kind of conductor is easy to generate higher heat. Therefore, when selecting the connector, the material of the conductor should be determined from the supplier and the current test should be done.

The circuit board of the light strip is too thin

If the circuit board of the light strip is too thin, it will cause the light strip to generate serious heat during operation, which will be transferred to the conductor of the connector. Another adverse effect is that it may cause insufficient contact and ignition, which will also increase the temperature. If the light strip is very thin, heat generation should be avoided by reducing the length or power.

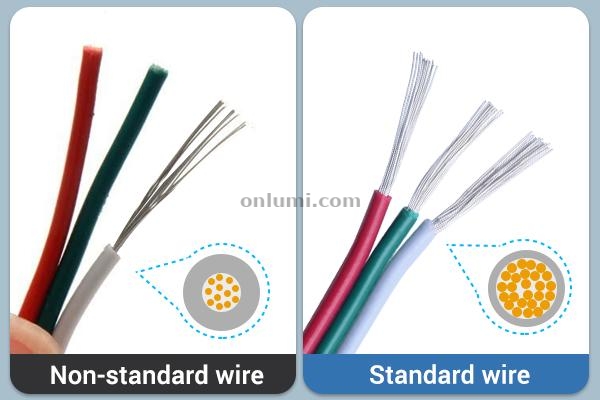

Use a Non-standard wire

This will cause the wire to generate heat, which will also be transferred to the hardware of the connector. Non – standard wire rod usually use copper wire with smaller diameter than standard copper wire as the wire core. Although the cost is saved and the price advantage is obtained, the overcurrent capacity is weakened because of the small cross-sectional area. In this case, if you supply power according to the current standard of the standard wire rod, it will causes the wire rod to generate heat and the outer skin of the wire to soften.

Check whether the wire rod is qualified by checking the certification number on the wire insulation. Generally, the wire rod with certification number is a standard one.

Poor environmental heat dissipation capacity

If the heat cannot dissipate into the air in time, the accumulated heat will cause the connector to overheat. Therefore, you should ensure that the ambient temperature is not too high and do not wrap the connector with thermal insulation material.

Short circuit

Short circuit will make the current of the circuit rise sharply and make the conductor heat. The short circuit is generally caused by the short circuit of the light strip itself and the short circuit of the conductor inside the connector. Therefore, avoid using non-waterproof connectors in humid environment, and avoid careless direct connection of the positive and negative poles of the light strip.

Plastic parts deformation

Plastic parts deformation will cause buckle failure. Usually, plastic parts deformation is due to unstable materials and poor storage.

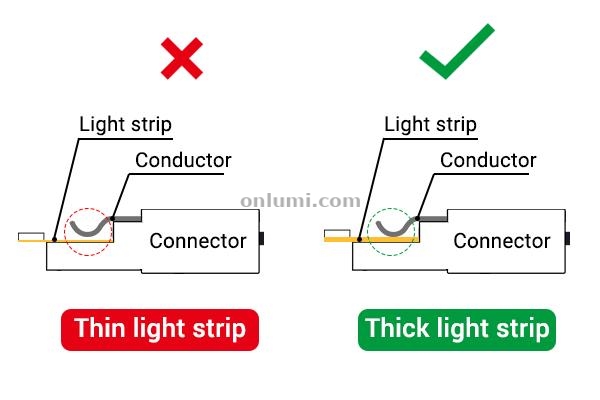

The light strip is too thin

This will cause the hardware to fail to hold the light strip because there is a partial gap between the two.

The hardware design is unreasonable

The hardware is not designed to prevent falling off, and the surface is too smooth to provide enough friction.

Without back glue connection

The back glue can increase the thickness of the light strip and the friction. If the back glue is removed, only the metal circuit board is left, the friction between plastic and metal will be weakened, which is easier to fall off.

Without checking whether the cover is fastened

When closing the cover, the buckle position shall be checked to ensure that each buckle point is buckled correctly.

The material is not flexible enough

Some materials are brittle and easy to fracture. When using them, the manufacturer’s reminder should be paid attention to.

Effects of ultraviolet rays

Ultraviolet rays have an aging effect on most plastics. It should be protected from direct sunlight or should not be in places with strong ultraviolet rays. It’s best to do occlusion processing.

The ambient temperature is too low

Extremely low temperature will cause the connector to become brittle and easy to fracture.